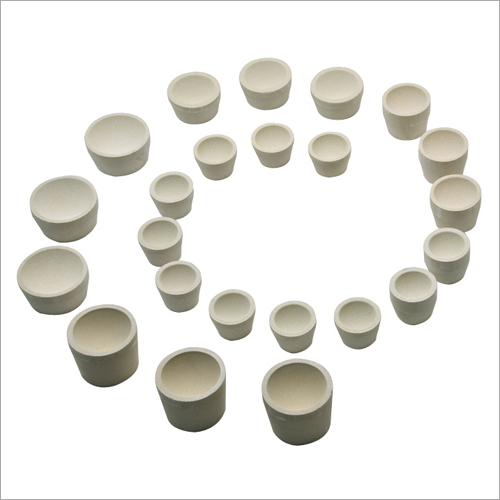

Magnesia Cupels

Magnesia Cupels Specification

- Surface Finish

- Smooth, slightly porous

- Melting Point

- 1700C - 2000C (approx)

- Purity(%)

- 97% 99%

- Usage & Applications

- Fire assay in mining, laboratories for separation of precious metals

- Hardness (%)

- Approx. 50 65 (Shore D)

- Density

- 2.3 Gram per cubic centimeter(g/cm3)

- Application

- Gold and silver assay, precious metal analysis

- Chemical Composition

- Over 97% MgO

- Water Absorption

- 7% 14%

- Form

- Solid, molded cup

- Product Type

- Assay Cupel/Refractory Cupel

- Types of Refractories

- Basic Refractory

- Shape

- Cupel (dish-like)

- Porosity

- High (absorbent for litharge/lead oxide)

- Dimensional Stability

- Excellent at high temps

- Strength

- High mechanical strength

- Specific Gravity

- 2.3 2.5

- Thermal Conductivity

- Low

- Color

- White/Grey

- Temperature Resistance

- Withstands thermal shock and repeated heating

- Packaging

- Standard export packaging or as required

- Bulk Density

- Approx. 2.2 g/cc

- Customization

- Available as per requirement

- Storage Condition

- Store in dry, moisture-free area

- Absorbency

- Excellent absorption of litharge and other fluxes

- Lead Removal Efficiency

- 99% and above

- Capacity

- Typically 20 gm and 30 gm (custom sizes available)

- Shelf Life

- 2 years under proper storage

Magnesia Cupels Trade Information

- Minimum Order Quantity

- 5 Metric Tons

- Supply Ability

- 50 Metric Tons Per Month

- Delivery Time

- 45 Days

- Main Domestic Market

- All India

About Magnesia Cupels

Size 1 Magnesia Cupels are widely praised and demanded due to their excellent strength and workability. These are mainly utilized for the purification of metals like gold and silver by absorbing the lead impurities present in it. These are highly efficient and does not crack or break over the course of time. Our Size 1 Magnesia Cupels are highly reliable and affordable.

Other Detail :-

Application : Industrial;,Commercial

Color: Milky White

Material: Magnesia

Mgo Content: 99%

Size: Customize

Features :-

- Portable

- Less Maintenance

- Durable

Exceptional Thermal Resistance

Magnesia Cupels are engineered to resist extreme temperatures, with a melting point ranging from 1700C to 2000C. Their ability to withstand thermal shock ensures dependable performance during repeated heating cycles in metallurgical assays.

Superior Absorbency and Purity

With a high absorbency rate for litharge and other fluxes, these cupels facilitate effective separation of precious metals. Their chemical composition, containing over 97% pure MgO, contributes to reliable results and efficient lead removal.

Custom Sizes and Versatile Applications

Available in typical capacities of 20 gm and 30 gm, Magnesia Cupels can be customized for various requirements. They serve fire assays in mining laboratories, supporting accurate gold and silver analysis for distributors, exporters, and manufacturers.

FAQs of Magnesia Cupels:

Q: How are Magnesia Cupels used in the fire assay process for gold and silver analysis?

A: During the fire assay, Magnesia Cupels absorb litharge and other fluxes, separating lead from precious metals like gold and silver. Their high absorbency and durability help ensure accurate results during the assaying procedure.Q: What are the storage requirements for maintaining the shelf life of Magnesia Cupels?

A: Magnesia Cupels should be stored in dry, moisture-free areas to preserve their shelf life, which is two years under proper storage conditions. This prevents degradation and maintains their absorbency and structural integrity.Q: When is it beneficial to choose Magnesia Cupels with custom sizes for laboratory use?

A: Custom sizes are advantageous for accommodating specific sample quantities or unique furnace configurations in various laboratory and mining settings, offering flexibility for different testing protocols and requirements.Q: Where are Magnesia Cupels commonly applied beyond precious metal analysis?

A: Apart from gold and silver assay, Magnesia Cupels are utilized in mining laboratories and metallurgical facilities for separation processes involving precious metals, benefitting exporters, distributors, and manufacturers.Q: What process enables Magnesia Cupels to achieve high lead removal efficiency?

A: The high porosity and purity of Magnesia Cupels allow efficient absorption of litharge, enabling them to remove lead with 99% or higher efficiency during fire assay operations.Q: How does the chemical composition of Magnesia Cupels influence their performance?

A: Containing over 97% MgO, their chemical stability and basic refractory nature grant high mechanical strength, low thermal conductivity, and excellent resistance to thermal shock and flux absorption, supporting reliable assay outcomes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Magnesia Cupels Category

Magnesia Cupels

Minimum Order Quantity : 1 Metric Ton

Product Type : Other, Fire Assay Cupel

Water Absorption : <20%

Form : Solid, Cup

Thermal Conductivity : Low

Types of Refractories : Basic Refractory

7AL Magnesia Cupels

Minimum Order Quantity : 5 Metric Tons

Product Type : Other, Cupel

Water Absorption : Low

Form : Solid

Thermal Conductivity : Low

Types of Refractories : Other, Basic

Magnesia Refractory Bullion Cupels

Minimum Order Quantity : 5 Metric Tons

Product Type : Other, Magnesia Refractory Bullion Cupel

Water Absorption : High for absorption of lead oxide

Form : Solid Cupel

Thermal Conductivity : Low

Types of Refractories : Basic Refractory

7X Magnesia Cupels

Minimum Order Quantity : 5 Metric Tons

Product Type : Other, Refractory Cupel

Water Absorption : Very low

Form : Solid Cupel

Thermal Conductivity : Low

Types of Refractories : Basic Refractory

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS