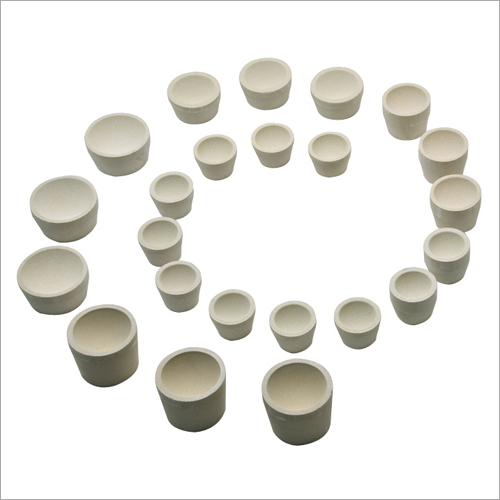

Magnesia Cupels

Price 2500.0 INR/ Metric Ton

Magnesia Cupels Specification

- Usage & Applications

- Quantitative Gold and Silver Analysis, Precious Metal Recovery

- Surface Finish

- Smooth, Non-Glazed

- Melting Point

- Above 1600C

- Form

- Solid, Cup

- Chemical Composition

- MgO 98%, SiO2 <1%

- Application

- Gold and Silver Assaying, Fire Assay

- Hardness (%)

- Approximately 80%

- Water Absorption

- <20%

- Purity(%)

- 98 99%

- Density

- 2.0 Gram per cubic centimeter(g/cm3)

- Product Type

- Fire Assay Cupel

- Types of Refractories

- Basic Refractory

- Shape

- Cup-shaped, Shallow Dish

- Porosity

- Controlled, 28-32%

- Dimensional Stability

- Excellent at High Temperatures

- Strength

- High Compressive Strength

- Specific Gravity

- 2.5 3.05 g/cm

- Thermal Conductivity

- Low

- Color

- White/Grey

- Packing Type

- Corrugated Boxes or Custom Packaging

- Typical Batch Size

- 500 1000 Pieces

- Thermal Shock Resistance

- High

- Dimension

- Available in 8g, 10g, 15g, 20g, 30g, 35g, 40g Standard Sizes

- Ash Release

- Minimal Ash Production During Assay

- Shelf Life

- 1218 Months Under Proper Storage Conditions

- Cupel Volume

- Variable, typically 3050 ml

- Lead Absorption Capacity

- Up to 80% by Weight

- Moisture Content

- <1% at Packaging

- Eco-Friendliness

- Non-Toxic, Crystalline Structure, Environmentally Safe

- Compatibility

- Suitable for Most Modern Assay Furnaces

Magnesia Cupels Trade Information

- Minimum Order Quantity

- 1 Metric Ton

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 50 Metric Tons Per Month

- Delivery Time

- 45 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Africa

- Main Domestic Market

- All India

About Magnesia Cupels

We are counted amongst the reputed names of market actively involved in providing a remarkable range of Magnesia Cupels to our customers. These are manufactured from the quality approved materials to ensure their highest strength and durability. Moreover, these Magnesia Cupels are maintenance free and available in a diverse range of specifications as per demands.

Other Detail :

Application : Industrial;,Commercial

Color: Milky White

Material: Magnesia

Mgo Content: 99%

Size: Customize

Superior Fire Assay Performance

Magnesia Cupels provide high accuracy and reliability in quantitative analysis of gold and silver. Their unique crystalline structure and basic refractory nature guarantee minimal ash release and excellent lead absorption, even at extreme temperatures. Controlled porosity enhances separation efficiency while the smooth surface prevents sample loss during the assay process.

Environmentally Safe and Durable

With a composition of 98% MgO and less than 1% SiO2, these cupels are non-toxic, environmentally friendly, and offer low thermal conductivity. Designed for durability, they exhibit high compressive strength and remarkable resistance to thermal shocks, maintaining stability and effectiveness through rigorous usage in assay furnaces.

Consistent Quality and Flexible Sizing

Available in standard sizes ranging from 8g to 40g and variable volumes (3050 ml), each batch is quality-tested for optimal moisture content (<1%) and density (2.0 g/cm). Magnesia Cupels are securely packed in corrugated boxes or custom packaging, ensuring safe transport and a shelf life of 1218 months with proper storage.

FAQs of Magnesia Cupels :

Q: How are magnesia cupels used in gold and silver assaying?

A: Magnesia cupels are primarily used in the fire assay process to separate precious metals (gold and silver) from lead and other impurities. The sample and lead are melted together in the cupel at high temperatures, where the cupel absorbs the lead oxide, leaving behind pure metal beads for analysis.Q: What benefits do magnesia cupels provide over other types?

A: Magnesia cupels offer superior thermal shock resistance, minimal ash production, and high lead absorption (up to 80% by weight). Their high MgO purity (9899%), controlled porosity, and smooth surface also enhance accuracy, reduce contamination, and facilitate easier metal recovery.Q: When should I choose specific dimensions of magnesia cupels?

A: Select the cupel size based on the sample amount and assay requirements. Smaller sizes (8g15g) are used for low-volume or laboratory tests, while larger sizes (20g40g) are preferred for bulk sampling or industrial-scale analyses. The variable volume (3050 ml) accommodates diverse operational needs.Q: Where can magnesia cupels be used?

A: Magnesia cupels are suitable for most modern assay furnaces and are widely used in analytical laboratories, mining companies, precious metal refineries, and research facilities involved in gold and silver analysis and recovery processes.Q: What is the process for using these cupels in a fire assay?

A: In a typical fire assay, the ore sample is mixed with flux and lead, placed in the magnesia cupel, and heated in a furnace above 1000C. As the lead oxidizes, the cupel absorbs the lead oxide, allowing the remaining gold and silver alloy to be collected for quantitative analysis.Q: What precautions should be taken for storage and handling?

A: Store magnesia cupels in a dry environment, away from moisture, as their moisture content should remain below 1%. Proper packaging in corrugated boxes helps prevent damage. Under these conditions, cupels maintain quality for 1218 months.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Magnesia Cupels Category

7AS Magnesia Cupels

Minimum Order Quantity : 5 Metric Tons

Thermal Conductivity : Very low

Application : Precious metal assay gold and silver refining

Strength : High crushing and thermal strength

Water Absorption : Very low, less than 0.5%

Hardness (%) : Above 70%

3S Magnesia Cupels

Minimum Order Quantity : 5 Metric Tons

Thermal Conductivity : Low thermal conductivity for efficient thermal insulation

Application : Gold and silver assaying, precious metal analysis, refining laboratories

Strength : High cold and hot crushing strength, > 15 MPa

Water Absorption : High, designed for efficient absorption of litharge (lead oxide)

Hardness (%) : Hard, resists abrasion during process

Size 8 Magnesia Cupels

Minimum Order Quantity : 5 Metric Tons

Thermal Conductivity : Low

Application : Laboratory use for precious metal assay and analysis

Strength : High compressive strength, designed to withstand rapid heating

Water Absorption : High, suitable for cupellation process

Hardness (%) : Approximately 7080%

Magnesia Cupels

Minimum Order Quantity : 5 Metric Tons

Thermal Conductivity : Low

Application : Gold and silver assay, precious metal analysis

Strength : High mechanical strength

Water Absorption : 7% 14%

Hardness (%) : Approx. 50 65 (Shore D)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS